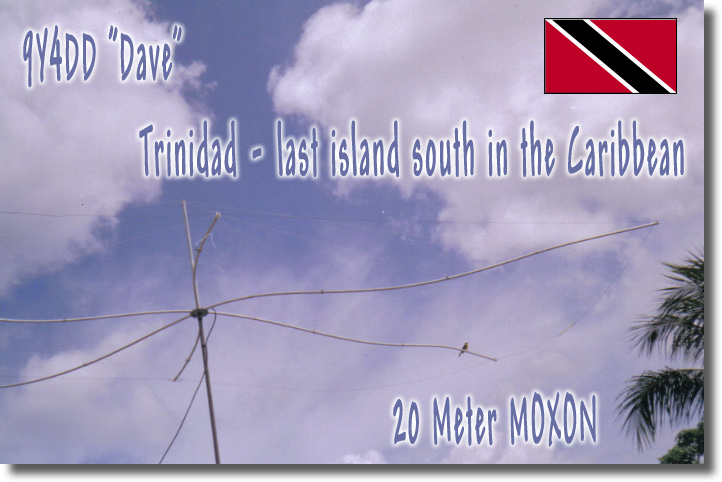

Here is 9Y4DD's "Dave" 20 meter homebrew MOXON at 15 feet. Note the small bird perched at the end of one of the spreaders.

Dave was searching the web for a better antenna to replace his inverted "V" for 20 Meters. As space is a problem for him, he had just about made up his mind to purchase the Hi-Gain Thunderbird Junior. But then he came upon the MOXON and immediately fell for it.

After the information and encouragement he received from various members of the MOXON Antenna Project, Dave started thinking and planning the building of this antenna. His aim was not to save money, but to show how inexpensive this antenna can be built, using materials just lying around the house.

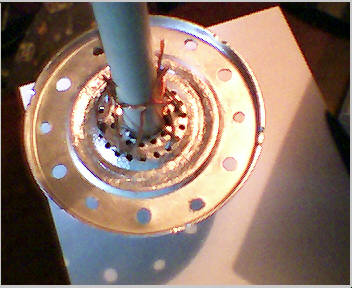

Dave changed the non-functioning pressure tank on his domestic water pump (which is a requirement here in Trinidad as residents sometimes experience low water pressure) a few months before. He had intended to discard it, but thought then that he might find some other use for it at a later date. Dave says that he is not one who easily discards junk and is noted for keeping some junk for several years, much to the displeasure of his XYL. Dave determined right away that this discarded pressure tank would serve well as a center mounting bracket for his MOXON. (See photo at left)

Note the six hold down bolts which conveniently became the perfect angles for attaching for each spreader. This bracket is six inches in diameter and has a 1" API thread connection for screwing into the pump. Dave also knew that this could be mounted directly by screwing onto a 1" galvanized pipe mast. This bracket held up a pressure tank of 24 liters water capacity (equivalent weight of over 50 lbs.) and so he thought a light weight antenna like the MOXON would surely be no problem.

Dave extracted the bracket and drilled six additional holes to accommodate U-bolt clamps for the spreaders and two short supports. Other available holes in the bracket (that worked as a strainer) allowed him to use stiff wire to further help 'tie' down the spreaders. Dave found some pieces of PVC conduit lying around and decided to use 1/2" PVC conduit for the spreaders, as the crappie poles are not available here. As these are so flexible, he decided that he would have to use a center projection to attach guy lines to the spreaders. He used a 4 foot piece of 3/4" PVC conduit for this, which fit so snugly into the ID of the 1" pipe connection that no fasteners were required. (See photo at right)

Dave then found a 6 foot length of 1" galvanized pipe in his storeroom with threads on both ends (what luck!), which he drove 1 foot into the ground so he could work on the antenna at eye level (5 feet). He screwed the center bracket onto the pipe using a 1" galvanized collar and got to work. He used 1 and a 1/2 lengths of 1/2" PVC conduit (which comes in lengths of 9' 6") for each spreader. Dave found a roll of waxed twine in the shack which was ideal for the guy lines. After clamping down the spreaders to the bracket and tying the guy lines from the top of the center projection to the point where the conduit was joined (at 9-1/2 feet from center) he was totally disappointed. The spreaders were dancing (fluttering) all over the place with the wind and even 'danced down to the ground'. The 3/4" conduit center projection was also too flexible and tilted to one side. (The photo at left shows the disaster)

Dave thought about how he could stabilize the spreaders, whose wall thickness is only 1/16". He then found a piece of 1/2" CPVC hot water pipe and discovered that it fits snugly into the 1/2" conduit. This CPVC pipe has a wall thickness of 3/32". So he thought that he could reduce the flexibility of the conduit by inserting 1/2" CPVC pipes into all the spreaders. This incurred the highest expense for this antenna and doubled its cost as well as doubled the weight of the spreaders. But the weight turned out to be good as it prevents upward fluttering with the wind. Having reduced the flexibility of the spreaders by the insertion of the CPVC pipe into the conduit, he then had to make stiff the center projection. He found the XYL's broom and 'decapitated' it of its handle which fit snugly into the 3/4" conduit and needed no fasteners.

Having solved those problems, or so he thought, Dave returned at working on the antenna again and anxious to get his MOXON built. However, he was again disappointed as his spreaders still danced too much with the wind. He decided then that he would call this antenna "The Wind Dancer". Dave was about to give up on the PVC spreaders and cut some bamboo poles, but persevere a bit more. He fabricated two sort of hexagonal 'spider webs' interconnecting the spreaders and two short supports with the same waxed twine; the first at 3-1/2 feet out from center on the spreaders and 3 feet on the short supports; the second at 7 feet from center on the spreaders and at the end on the two short supports. This stabilized his spreaders.

Dave then carefully did some measurements, because he wanted to cut the spreaders to the exact length needed for 20 Meters, as he decided he would use 1/2" PVC conduit ends at the end of each spreader and the two short supports for neatly holding the antenna, for which he used 2.5mm. sq. stranded copper wire (the standard electrical wire with the insulation taken off). After some meticulous measurements, he determined that the spreaders needed to be 165 inches from center and he had to cut off only a few inches of each. He found a PVC 4" x 4" electrical box in the shack, which he decided to dissect to make tabs from for holding the wire by securing the tabs with the locknuts. He knocked out the holes and began to cut. (See photo at right)

Dave drilled two 1/8" holes in each tab for the corners to pass the wire through and make for a neat corner. (See photo at left)

Tension on the wire could be increased by simply twisting on the corners with a pair of pliers. However, he did not have to resort to that.

Dave also made a tab from the PVC electrical box for the center connection in which he drilled two 1/8" holes to hold the two sides of the driven element and passed the coax cable through the pipe for connection to the antenna at the center connection. (See photo at right)

Dave found in a piece of 3/16" white Plexiglas in his storeroom which he had salvaged from a broken Texaco service station sign about three decades ago. From this he cut two 1" wide pieces 9-1/4" long for use as the separators, drilling two 1/8" holes in each at the required distance apart of 8.6". (See photo at left)

Dave mounted the copper wire, which further stabilized the spreaders as the final 'web'. The specifications provided by L.B. Cebik (W4RNL) were fully adhered to. He found that the counterbalance weight between the center and the guy line on each spreader prevented the ends from drooping below the level of the center bracket when sufficient tension was applied to the wire and he was happy with that. He achieved full tension on the long sides of the rectangle. The separators hang a bit, though, but Dave says that he can live with it. Because of the design of the antenna it is hard to get full tension on the short sides. The ends of the spreaders dance just a bit in high winds but it is nothing to be concerned about.

At six feet off the ground, Dave tested the antenna. He got SWR readings of 1.2 at 14.000 MHz, 1.4 at 14.350 and 1.1 at 14.175. He was happy with those readings and saw no need for adjusting. As he tested the antenna at six feet, it was pointing N.E. to Europe resulting in an immediate QSO with S51CK in Slovania. Dave got a signal report of S-5/7 transmitting 100 watts. He switched between the MOXON and the inverted "V" and realized the background noise heard with the "V" was absent with the MOXON.

Dave subsequently raised the antenna to 15 feet and noticed that the SWR increased by 0.1 on all three test frequencies. However, he is now receiving better signal reports and finds himself working many European DX contacts. Dave plans to eventually raise the antenna to 30 feet.

Below is a tabulation of the materials used with their corresponding weight and cost.

|

MATERIALS WEIGHT COST

(pounds) (U.S. $) Center Bracket 0.750 - 3/4" Center Projection 1.125 - 1/2" PVC Conduit 4.750 7.00 1/2" CPVC Hot Water Pipe 4.750 18.63 Clamps, Clips & Fittings 0.625 7.00 Seperators, Twine & Tabs 0.125 - Wire 0.500 4.00

Total Weight is 12.625 Lbs. Total cost is U.S.$36.63. |

Dave's MOXON can stay up as long as the waxed twine holds up. If this antenna is to be dismantled, all the materials used could go back to use for their original purposes. No holes were drilled in the pipes. The collars used for joining the conduit pipe have a lip on one side. Dave positioned the lip on the outer side of the spreader and the lip was wide enough to tie the guy line against. The center bracket can even go back to use on the pressure tank, which is reusable by putting in a replacement diaphragm.

Email Dave at winddancer@tstt.net.tt for additional information about his 20 meter MOXON.