Bill of materials:

Hand tools:

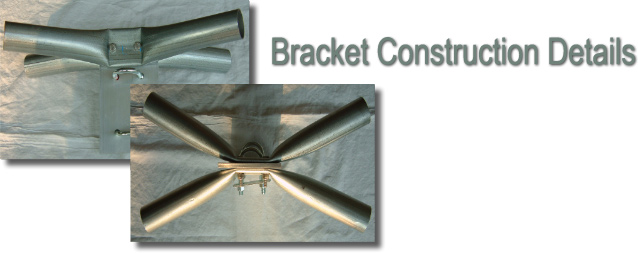

Building the bracket:

1 piece of aluminum plate 4" x "7" x 1/4" (available at most machine shops or metals dealers for about $4.00)

1 length of 1 1/4 steel electrical conduit. (10 ft length is about $4.00 at Home Depot or Lowes)

2 pipe type u-bolts for mast clamp ( $0.91 each at Home Depot or Lowes)

2 5/16 bolts 2 inches long ( less than a dollar anywhere)

6 locking nuts for the above (about $0.35 each)

Hand tools:

Center punch to mark hole locations on bracket.

Electric drill or Drill press

Appropriate drill size for clearance holes for 5/16 bolts and u-bolts

Hand file

Vise grip pliers

Special services required:

To press the flats on the conduit you need access to a small hydraulic press. A twelve ton press is sufficient. Most auto repair shops, transmission repair shops, machine shops, welding shops have these or larger presses. Many farmers also have these presses.

Building the bracket:

Cut 2 pieces of conduit that are 16 inches long.

Deburr the cut ends of the conduit both on the outside diameter and the inside diameter.

Have a 2 1/2 inch flat pressed in the center of each of the pieces of conduit. This conduit is welded so keep the weld bead (some what hard to see, but runs length wise down the tubing ) face down when pressing the flats. Then while supporting each end of the conduit with two pieces of 2x4 stud, material press each piece again until you have a 22 1/2 degree angle.

Lay out the plate, center punch the holes and drill them.

Using the vise grips as a temporary clamp, drill holes in the conduit flats using the mast plate as a drill jig.

Deburr the drilled holes on the mast plate and the brackets and then assemble the mast bracket. If you don't have a 45 degree angle between the two brackets you can place the bracket in something like a trailer hitch for leverage and bend them a bit more.