...featuring "yagi style" aluminum tubing design for greater durability

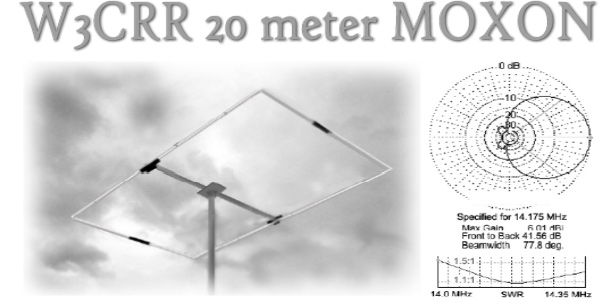

W3CRR's "Craig" 20 meter MOXON attached to his chimney. The boom, mount and mast are Schedule 90 and 120 PVC and the elements are drawn aluminum tubing from Texas Towers. Craig used weather-protectred coax connectors near the mount for convenience and installed a 1:1 toroid balun inside the boom near the feedpoint.

Craig says that the antenna works well. Pointed toward Europe, his very first report with it was a "5-9 plus" from Bulgaria!

According to DX Engineering Yagi Mechanical software calculations, the wind speed survival of this 20 meter design should be 103 plus MPH. Craig is also at work designing higher band models which will feature a one-piece boom and higher weather survival ratings.

Structural diagram for W3CRR 20 meter MOXON

Detail A -- Aluminum tubing junction. Note the "Button" type hex head bolts designed to distribute contact force over a large area to maintain best electrical contact between element sections. All element joints are treated with Penetrox.

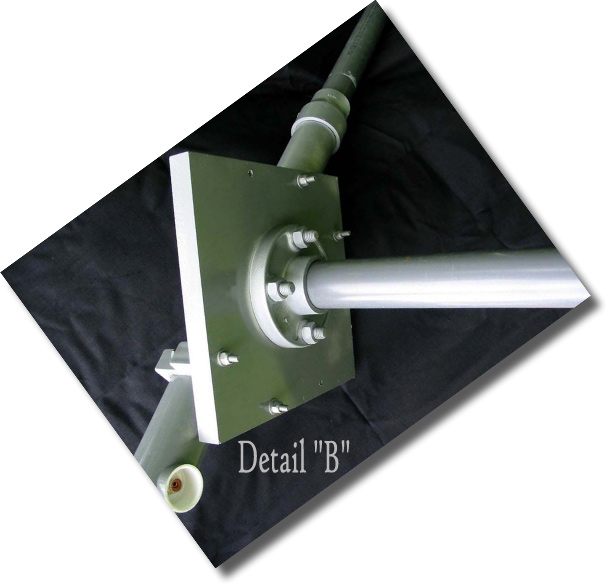

Detail B -- Boom to mast bracket (underside). The mounting plate on this large, 20 meter antenna is one-inch thick PVC and mates to a 1-1/2 inch PVC mast via a heavy duty PVC flange. These components can be increased to 2 inch diameters, if desired. The all-plastic construction eliminates any possible metallic interaction with the Moxon elements -- although this is not strictly necessary. The primary advantage of the PVC construction is its

ruggedness. Note the recessed, weather protected SO-239 coax connector near the mounting plate.

Detail C -- Boom to mast bracket (topside). The boom's center section is 2 inch PVC pipe which mates to 1-1/2 inch end sections. This tapered design saves a considerable amount of weight on the 9 foot boom. Shorter booms on higher frequency antennas will be 2 inches throughout to eliminate sagging. The PVC boom, while heavier than aluminum, is stronger and resists almost any (realistic) wind without distorting permanently. All hardware on the mount is PVC and the whole assembly is cemented together to structurally form a nearly indestructible one-piece unit. All PVC

components are coated with a special, high-bond, flexible paint to resist UV exposure.

Detail D -- Feedpoint (underside). The center insulator on the driven element is solid, 3/4 inch acrylic rod. It adds structural strength to the element. The corresponding center section of the reflector is triple-thickness aluminum tubing.

Detail D -- Feedpoint (topside). The driven element feedpoint includes a 1:1 current balun hidden inside the boom for a neat installation.

Unassembled components of Craig's MOXON illustrating how a homebrew aluminum version can be broken down into six-foot sections for portable use. Craig says that he can assemble it in about 20 minutes.

Email W3CRR "Craig" at crgrbrts@verizon.net for additional information about his MOXON designs.