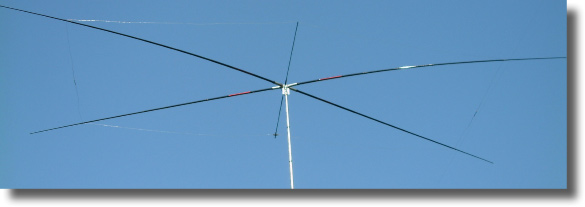

k4QKY's MOXON

Completed MOXON at 30 ft. on a push-up mast

Materials

![]() Top left, above photo: Side view of the 3 piece pole bracket assembly. Note

the 4"X6.75"X.25" mast bracket plate which was cut from 6061-T6 aluminum stock

with 4 holes drilled to accept two 2 mast clamp U bolts and 2 other holes for

attaching the 2 pole holders. Click

here for additional construction details.

Top left, above photo: Side view of the 3 piece pole bracket assembly. Note

the 4"X6.75"X.25" mast bracket plate which was cut from 6061-T6 aluminum stock

with 4 holes drilled to accept two 2 mast clamp U bolts and 2 other holes for

attaching the 2 pole holders. Click

here for additional construction details.

![]() Top right, above photo: Top view of the 3 piece pole bracket assembly. The

two pole holders are made of 1.25 inch electrical conduit and were compressed

and bent to form the correct 45 deg angle between opposing poles. Each pole

holder extends outward 7.50" from the mast. Click

here for additional construction details.

Top right, above photo: Top view of the 3 piece pole bracket assembly. The

two pole holders are made of 1.25 inch electrical conduit and were compressed

and bent to form the correct 45 deg angle between opposing poles. Each pole

holder extends outward 7.50" from the mast. Click

here for additional construction details.

![]() Center, above photo: This unique compact antenna uses a supporting structure

made with four 16 foot telescoping fiberglass crappie fishing poles. Poles are

from Tackleplus, model name Crapple Buster Deluxe, model number 1200-16BW available

from www.catfishsupplyco.com.

Center, above photo: This unique compact antenna uses a supporting structure

made with four 16 foot telescoping fiberglass crappie fishing poles. Poles are

from Tackleplus, model name Crapple Buster Deluxe, model number 1200-16BW available

from www.catfishsupplyco.com.

![]() Left bottom, above photo: The antenna's two elements are made using 16

gauge tinned copper antenna wire. Dacron line is used to strengthen the

structure and to separate the ends of the driven element from the ends of the

reflector.

Left bottom, above photo: The antenna's two elements are made using 16

gauge tinned copper antenna wire. Dacron line is used to strengthen the

structure and to separate the ends of the driven element from the ends of the

reflector.

![]() Right bottom, above photo: Driven element feed point connector.

Right bottom, above photo: Driven element feed point connector.

![]() Not shown: Miscellaneous hardware, wire tie wraps, electrical tape, etc.

Not shown: Miscellaneous hardware, wire tie wraps, electrical tape, etc.

Assembly

![]() Top left, above photo: Side view of the end of one of the four poles. Note

the ridge which had to be partially filed off in order to make it fit into the

end of the pole holders. Also note double sided tape (backing not removed) to

stabilize and cushion the pole in the pole holder.

Top left, above photo: Side view of the end of one of the four poles. Note

the ridge which had to be partially filed off in order to make it fit into the

end of the pole holders. Also note double sided tape (backing not removed) to

stabilize and cushion the pole in the pole holder.

![]() Top right, above photo: One of two insulators fashioned from nylon "weed

whacker" line.

Top right, above photo: One of two insulators fashioned from nylon "weed

whacker" line.

![]() Center, above photo: Assembled antenna temporarily mounted on a yellow

fiberglass pole for easy access. Note how each pole fits into the pole bracket

assembly. A green fiberglass "garden stake" runs from the center of the

reflector (extreme lower left corner) through a hole in the mast bracket to the

antenna feed point. Note: The

completed antenna remained over night 08/22/03 in it's temporary location shown

above. The antenna was entirely intact following a late night severe

thunder storm with 45 knot wind gusts attesting to it.

Center, above photo: Assembled antenna temporarily mounted on a yellow

fiberglass pole for easy access. Note how each pole fits into the pole bracket

assembly. A green fiberglass "garden stake" runs from the center of the

reflector (extreme lower left corner) through a hole in the mast bracket to the

antenna feed point. Note: The

completed antenna remained over night 08/22/03 in it's temporary location shown

above. The antenna was entirely intact following a late night severe

thunder storm with 45 knot wind gusts attesting to it.

![]() Left bottom, above photo: Driven element feed point assembly. Note green

fiberglass "garden stake" that supports the feed point and coax. It runs from

the center of the reflector (extreme lower left corner) through a hole in the

mast bracket to the antenna feed point.

Left bottom, above photo: Driven element feed point assembly. Note green

fiberglass "garden stake" that supports the feed point and coax. It runs from

the center of the reflector (extreme lower left corner) through a hole in the

mast bracket to the antenna feed point.

![]() Right bottom, above photo: Cable ties and electrical tape securing the

corners of each element to the pole spreaders. Note: The

completed antenna's flimsy construction presents some degree

of challenge in properly attaching the corners of the driven element and

reflector to the pole spreaders at equal distances.

Right bottom, above photo: Cable ties and electrical tape securing the

corners of each element to the pole spreaders. Note: The

completed antenna's flimsy construction presents some degree

of challenge in properly attaching the corners of the driven element and

reflector to the pole spreaders at equal distances.

Construction comments

![]() Isolation of the antenna from the push-up mast: The antenna was initially

attached directly to the mast as shown in the above photograph. However, upon

initial testing it was determined that the metallic mast and pole holders

severely detuned the antenna. To correct this problem, the antenna was

electrically isolated from the mast by the insertion of a 4 foot heavy duty

wooden broom handle (wrapped with electrical tape) 2 foot into the top section

of the push-up mast. The pole bracket assembly was then bolted to the top of

the broom handle. Subsequent SWR measurements indicate that the metallic pole

bracket itself may be the culprit. A non-metallic alternative pole bracket

assembly is currently being considered.

Isolation of the antenna from the push-up mast: The antenna was initially

attached directly to the mast as shown in the above photograph. However, upon

initial testing it was determined that the metallic mast and pole holders

severely detuned the antenna. To correct this problem, the antenna was

electrically isolated from the mast by the insertion of a 4 foot heavy duty

wooden broom handle (wrapped with electrical tape) 2 foot into the top section

of the push-up mast. The pole bracket assembly was then bolted to the top of

the broom handle. Subsequent SWR measurements indicate that the metallic pole

bracket itself may be the culprit. A non-metallic alternative pole bracket

assembly is currently being considered.

![]() Antenna dimensions calculated by the MoxGen program are generally valid:

Most builders of the MOXON will not find it necessary to lengthen or shorten any

of the wire lengths.

Antenna dimensions calculated by the MoxGen program are generally valid:

Most builders of the MOXON will not find it necessary to lengthen or shorten any

of the wire lengths.

![]() Difficulty making electrical tape stick to slippery poles. Electrical

tape was used to tape each pole joint as well as attaching the corners of each

wire element to the poles. Lightly sanding areas of the pole before taping

helps alleviate this problem.

Difficulty making electrical tape stick to slippery poles. Electrical

tape was used to tape each pole joint as well as attaching the corners of each

wire element to the poles. Lightly sanding areas of the pole before taping

helps alleviate this problem.

![]() The tradeoff to building a light weight antenna is reduced rigidity. The

antenna so light weight that it is easily rotated by hand. The ends of each

pole will naturally droop downward (like an umbrella) depending on the degree of

tension applied to the wire elements resulting from where they have been

attached to the poles. Employing a support pole from the center of the

reflector through the pole bracket assembly to the driven element feed point

helps stabilize the elements as well as the coax feed line.

The tradeoff to building a light weight antenna is reduced rigidity. The

antenna so light weight that it is easily rotated by hand. The ends of each

pole will naturally droop downward (like an umbrella) depending on the degree of

tension applied to the wire elements resulting from where they have been

attached to the poles. Employing a support pole from the center of the

reflector through the pole bracket assembly to the driven element feed point

helps stabilize the elements as well as the coax feed line.

Note: Click here to read Don's evaluation of his MOXON antenna's performance.

Email Don at k4qky@charter.net for additional information about his MOXON.